COOLING TOWER & AIR-COOLED CHILLERS

Upgrading the World’s Largest District Cooling Plant with ANSYS-CFX and Flowpak Engineers – Qatar Cool

Qatar Cool, a district cooling company in Qatar, has hired Flowpak Engineers to improve the efficiency of district cooling plant 01 in West Bay and GDCP cooling plant in Pearl Qatar.

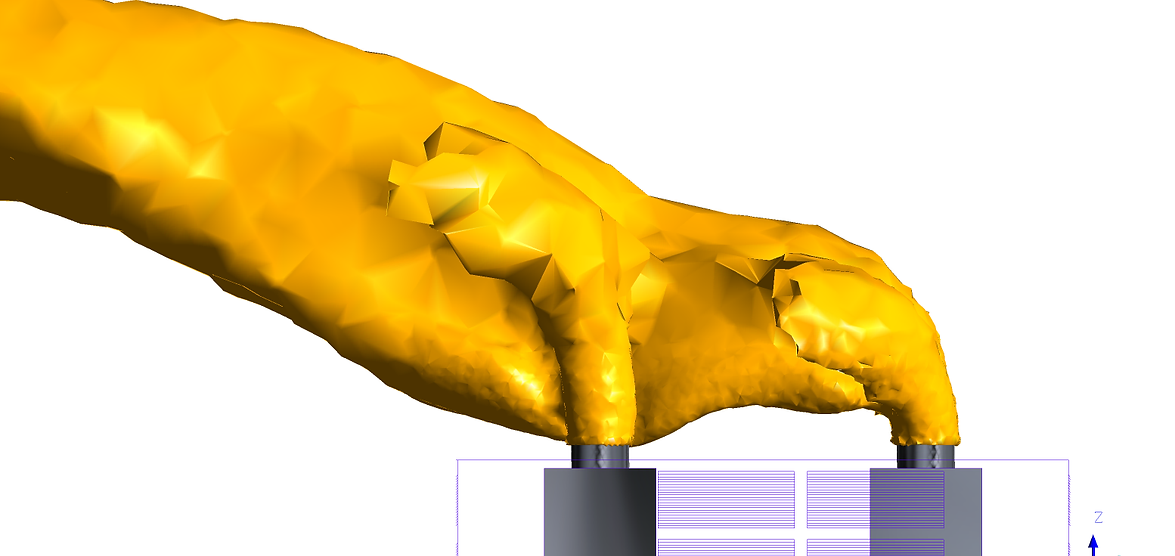

Using ANSYS-CFX, a computational fluid dynamics software, the team of experts studied the air recirculation problem and provided a solution to control it.

The engineers used CFD simulations to model fluid flow and heat transfer within the plant, identify recirculation areas, and develop a solution to improve the cooling system’s efficiency.

Reducing Cooling Tower Recirculation with ANSYS-CFX CFD Analysis

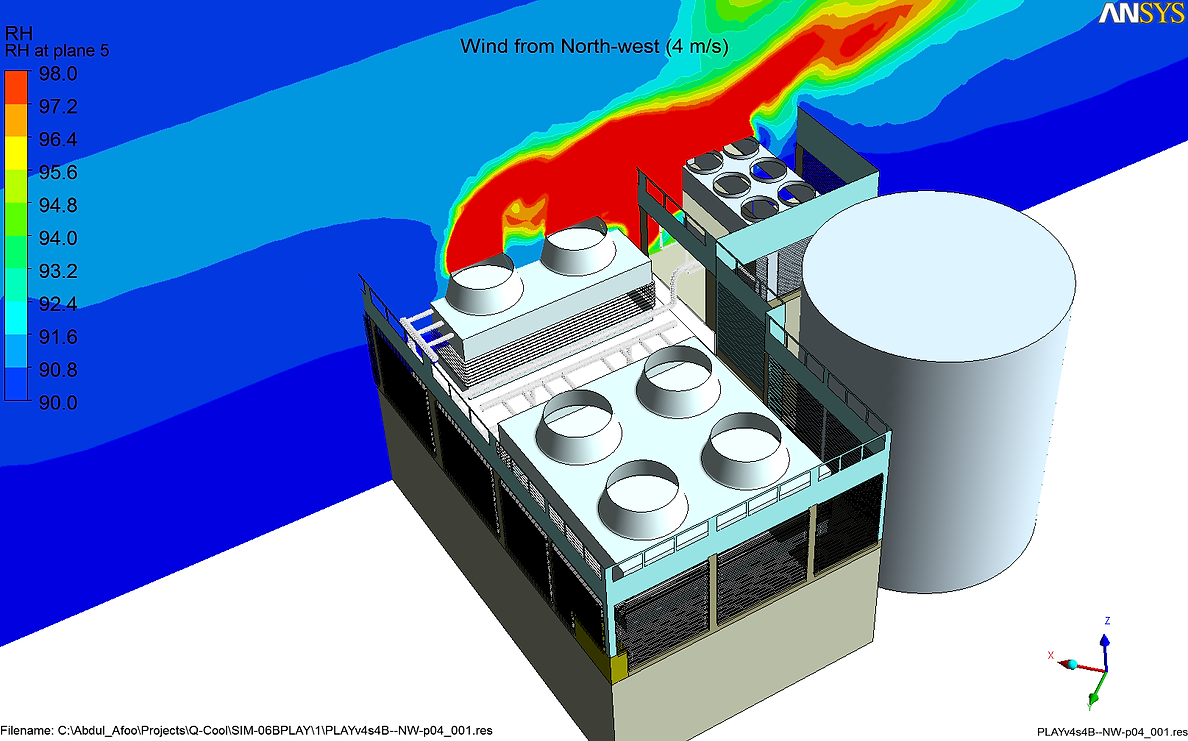

Air recirculation can have a significant impact on the performance of a cooling tower.

When air recirculation occurs, some of the warm air cooled by the tower is drawn back into the system and mixed with the incoming warm air.

This reduces the effectiveness of the cooling tower, as the warmer air will require more energy to be cooled. Additionally, recirculation can cause the formation of bacteria and other microorganisms, which can lead to health hazards and equipment failure.

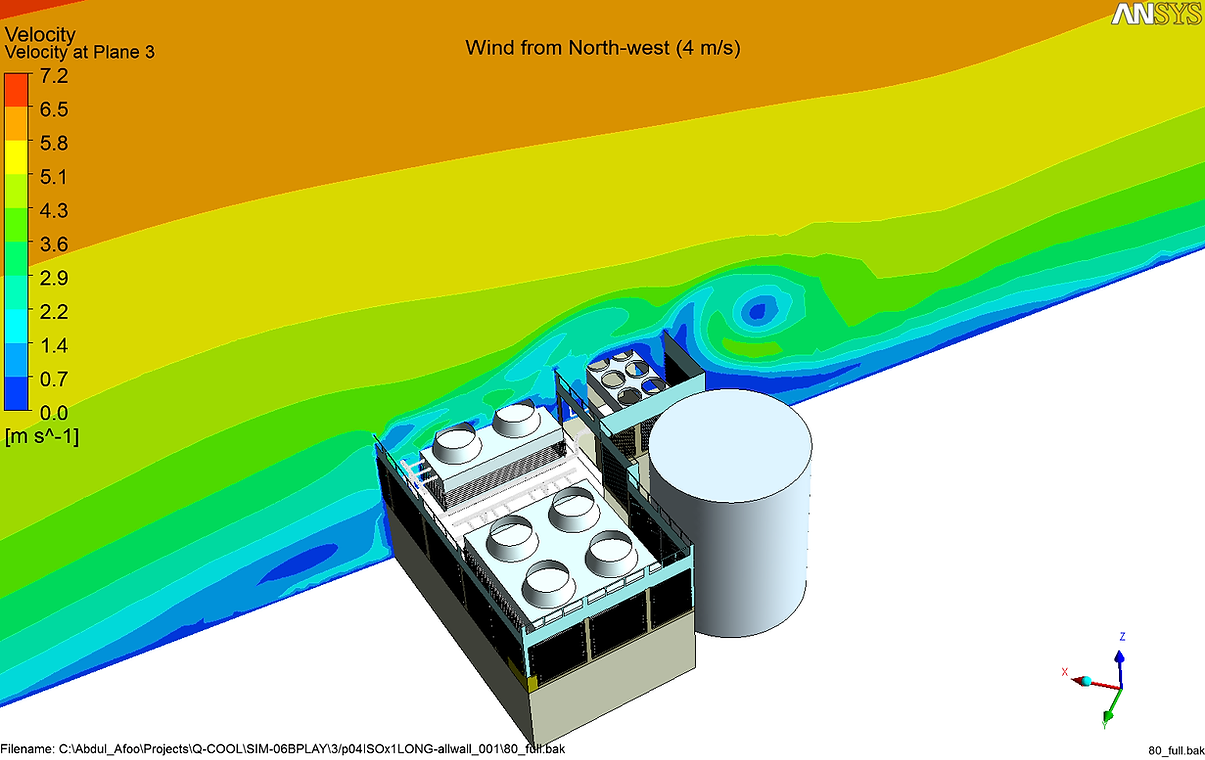

CFD (Computational Fluid Dynamics) can optimize the design and operation of cooling towers by simulating the airflow and heat transfer within the cooling tower and predicting the effects of different designs and operating conditions on the cooling tower’s performance.

It can also help to identify areas of recirculation and inefficiency and help to develop an optimal design that can operate efficiently under a wide range of conditions.

Enhancing Cooling Tower Plant Efficiency at Kuwait International Airport with ANSYS-CFX CFD Analysis

Flowpak was hired to study the air recirculation for the new cooling tower plant at the Kuwait International Airport as part of an extension project.

The goal was to optimise the space between the cooling tower cells and examine the architectural fence to ensure proper air recirculation for improved working efficiency.

Flowpak provided a solution by using CFD simulation with Ansys-CFX software.

Optimizing Air Recirculation at Marina Mall’s Cooling Tower Plant in Dubai UAE with CFD Simulation using ANSYS-CFX and Wet Bulb Temperature Consideration

Wet bulb temperature is an essential factor affecting cooling tower plants’ performance.

It is a measure of the amount of moisture in the air and has a direct impact on the efficiency of the cooling system.

By using CFD simulation with Ansys-CFX, Flowpak was able to simulate the airflow and thermal conditions within the cooling tower plant in Dubai Marina Mall, taking into account the wet bulb temperature and its effect on the performance of the cooling system.

This allowed Flowpak to identify areas where improvements could be made, such as changes to the design of the cooling towers, the placement of the architectural fence, or the overall layout of the cooling system.